Parking Garage Materials Comparison Guide

Whether your parking structure is new or has been standing for years, understanding which parking garage materials are most beneficial for your needs is key to extending its life cycle.

Continue reading our blog to discover the benefits of different types of parking garage materials and what StructureCare uses to ensure your parking structure remains healthy and strong.

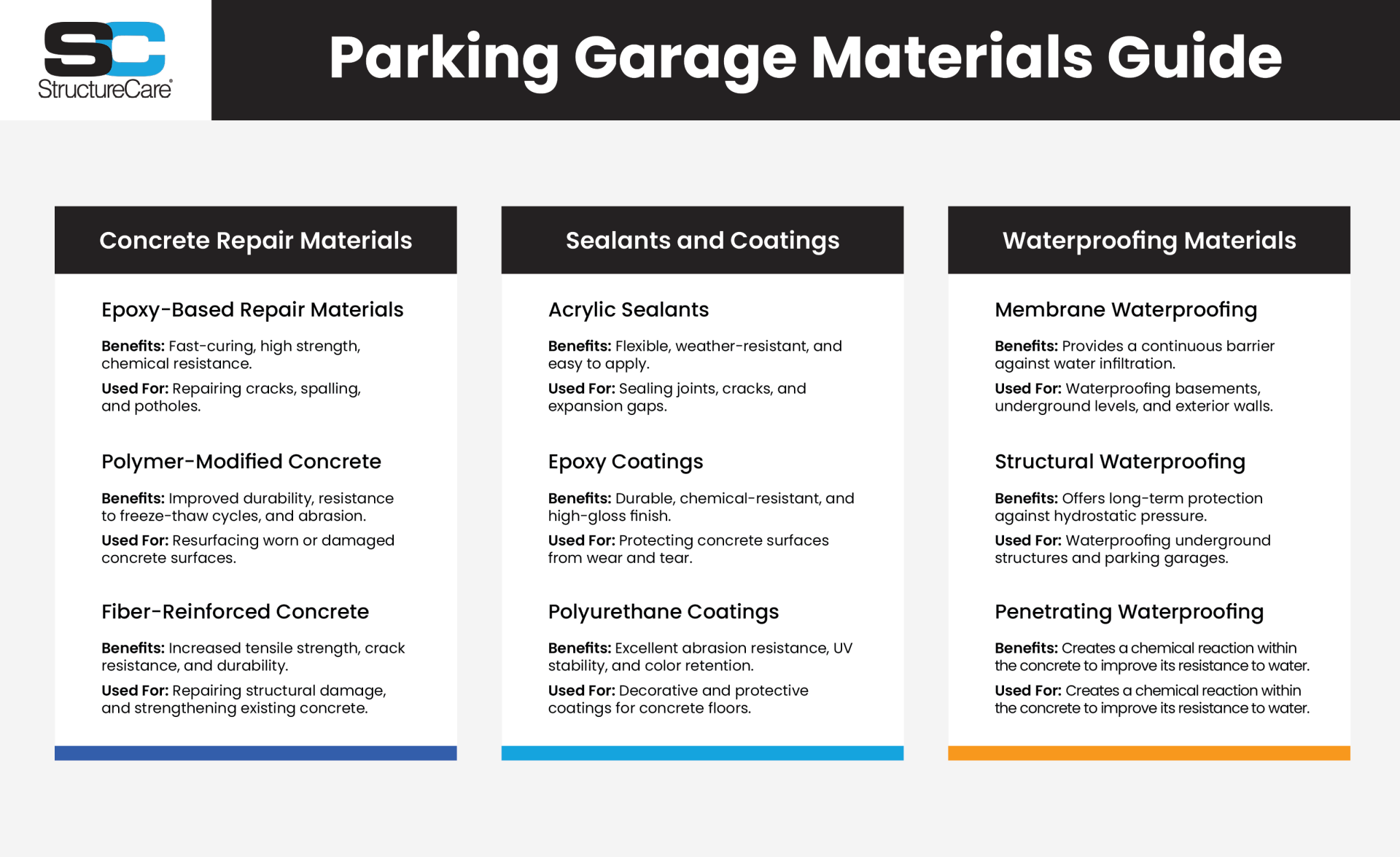

Parking Garage Materials Guide

When it comes to deciding the best parking garage materials to use for new and existing structures, there are many things to consider. Below, we’ve provided a comprehensive parking garage materials guide to help make your decisions easier.

Concrete Repair Materials

One of the main benefits of concrete parking garages is their ability to last years without deteriorating. However, even concrete can become worn or damaged after exposure to natural elements and without proper parking garage maintenance. The following parking garage materials are commonly used for concrete repairs and restoration projects.

Epoxy-Based Repair Materials

There are two main types of epoxy-based repair materials used for parking garages. Two-component epoxies require mixing resin and a hardener before application whereas one-component epoxies are pre-mixed and ready to use. Both types offer a variety of advantages including:

- Rapid curing times.

- High strength and durability.

- Excellent chemical resistance.

Epoxy-based repair materials are used for many applications from repairing cracks and spalls to bonding new concrete to existing surfaces. They also can be used to restore damaged edges and corners of your parking structure.

Polymer-Modified Concrete

As its name suggests, this material consists of concrete modified with polymers such as acrylics, styrene-butadiene rubber, or latex. Because of its unique composition, polymer-modified concrete provides parking structures with the following benefits:

- Improved durability and resistance to freeze-thaw cycles.

- Enhanced abrasion resistance.

- Better bond strength to existing concrete.

- Reduced shrinkage and cracking.

This parking garage material is often used for resurfacing worn or damaged concrete floors, repairing deteriorated concrete slabs, and creating decorative finishes.

Fiber-Reinforced Concrete

There are two main types of fiber-reinforced concrete. The first includes steel fibers while the second consists of synthetic fibers. Both types offer advantages such as:

- Increased tensile strength and toughness.

- Improved crack resistance and durability.

- Can be used for new parking structures as well as for repair projects.

Fiber-reinforced concrete is typically used for repairing structural damage to beams, concrete washes, and columns in your parking structure. However, they can also help strengthen existing concrete slabs and create high-performance concrete parking garage floors.

Sealants and Coatings

While they are often thought of as the same thing, sealants, and coatings are two different types of parking garage materials used to protect and repair concrete parking structures. Contrary to popular belief, you do not have to choose one over the other. In some cases, using both a sealant and coating can be beneficial in parking garage maintenance.

Sealants

Sealants are used to bridge gaps, cracks, and joints in concrete surfaces. This helps prevent water infiltration and reduce the risk of structural damage. Types of sealants vary depending on their composition and properties, some of these include:

- Acrylic sealants: flexible, weather-resistant, and easy to apply.

- Polyurethane sealants: durable, UV resistant, and color retention.

- Silicone sealants: highly UV resistant with enhanced elasticity, these are beneficial on exposed vertical joints.

Not only do sealants prevent water penetration and reduce the risk of corrosion, but they also improve the appearance of your concrete surfaces. Like many other parking garage materials we’ve mentioned, they also can be applied to new and existing concrete parking structures.

Coatings

Coatings provide a protective layer to concrete surfaces to enhance their durability and appearance and help resist various environmental factors that may cause deterioration. The three main types of coatings include:

- Epoxy coatings: durable, chemical resistant, with a high-gloss finish.

- Polyurethane coatings: durable, abrasion-resistant with UV-stable finish.

- Acrylic coatings: durable, weather resistant, and available in a variety of colors.

Coatings can help improve the overall performance of concrete parking structures by protecting your garage floors, walls, and other surfaces from stains, spills, and chemical damage.

Waterproofing Materials

Water and moisture-related problems are often the main culprits of deterioration in parking structures. As a result, it’s crucial to know which parking garage materials you should be using to fix waterproofing issues or prevent them from happening in the first place.

Membrane Waterproofing

Membrane waterproofing materials can be used for new construction projects or added to existing parking structures to provide barriers against water infiltration. There are three main types, all of which have different characteristics and properties:

- PVC membranes: flexible, durable, and resistant to chemicals and UV rays.

- EPDM membranes: rubber-based membranes known for their elasticity and long lifespan.

- TPO membranes: thermoplastic polyolefin membranes offering durability and chemical resistance.

Installing membrane waterproofing materials typically involves bonding the membrane to the substrate using adhesive or mechanical fasteners. In some cases, you may need to consider additional protection layers like ballast or geotextiles.

Structural Waterproofing

Offering long-term protection against hydrostatic pressure, structural waterproofing materials can be used in addition to other waterproofing methods. These parking garage materials are ideal for high-pressure applications, like underground parking structures. There are two main types:

- Bentonite-based waterproofing: uses bentonite clay to create a swelling barrier against water.

- Geosynthetic waterproofing: uses synthetic materials, such as geotextiles or geocomposites, to provide waterproofing and drainage.

These systems are installed by placing the waterproofing material between the structure and the surrounding soil. As a result, the process may require backfilling and compaction to ensure proper performance. In some cases, this is not feasible. In this case, a process called blind-side waterproofing is used where the material is injected or pumped from the inside.

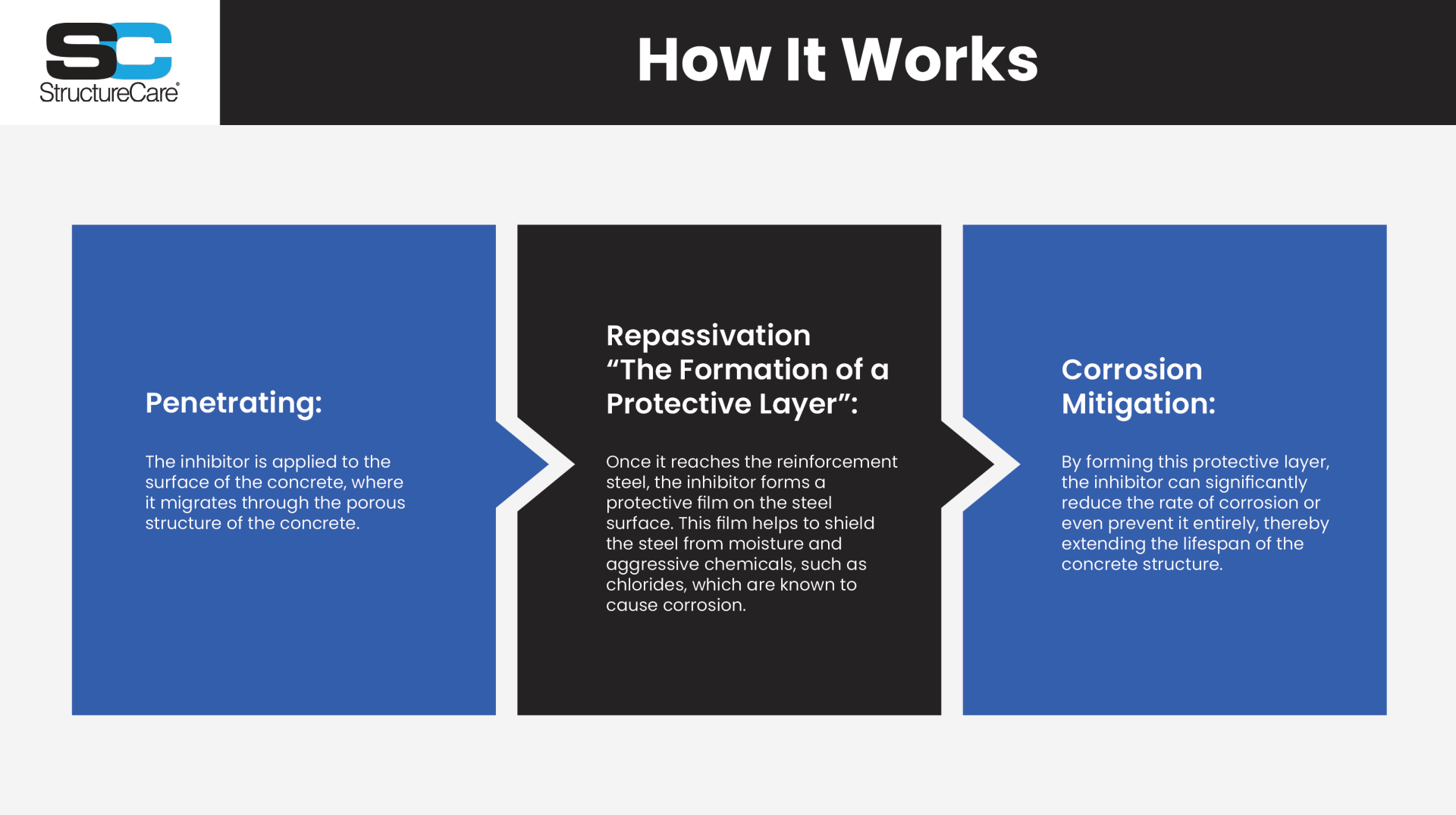

Penetrating Waterproofing

Unlike membrane waterproofing, these parking garage materials penetrate the concrete surface rather than sitting on top to create a barrier. There are two main types of penetrating waterproofing:

- Chemical-based penetrating sealers: react with the concrete to create a hydrophobic barrier.

- Crystalline sealers: form a network of crystals within the concrete to block water penetration.

Penetrating sealers can also be applied to new and existing concrete, but since they penetrate the surface, they tend to last longer. At StructureCare, we often specify the use of crystalline sealers. This product offers many unique benefits, which we will discuss in more detail in the section below.

What Is Unique About A Crystalline Sealer?

It is a clear, water and chemical-based dual crystalline penetrating sealer. It provides a permanent treatment to protect your concrete from water and moisture-related problems.

One of the reasons it is unique, and why StructureCare prefers it over other parking garage materials, is because it provides double protection against moisture penetration in concrete structures. By combining both hygroscopic and hydrophilic properties, it offers pore-blocking, as well as hydrophobic materials for pore-lining capabilities.

By reducing the moisture content of concrete, crystalline sealers can help reduce damage from a variety of water and moisture-related issues, including freeze-thaw cycles, chloride ion penetration, and alkali-silica reactions.

In addition to overall protection, there are several other advantages of using this type of material, such as:

- Maintaining your concrete structure’s natural appearance.

- Resisting aggressive chemicals.

- Reducing efflorescence.

- Being sustainable and environmentally friendly.

- Prolonging your concrete’s life cycle.

- Reducing maintenance and repair costs.

Need help navigating parking structure repairs? Talk to one of our experts to see how we can help today.

Problem? Question?

Let's solve it. And not just for today — for the long term, too.